- Free Sample

- Request Quote

(773) 277-1600 |

(773) 277-1600 | - ITAR Registered

-

-

-

Whitepaper: Metal Finishing

Electropolishing to Improve Corrosion Protection

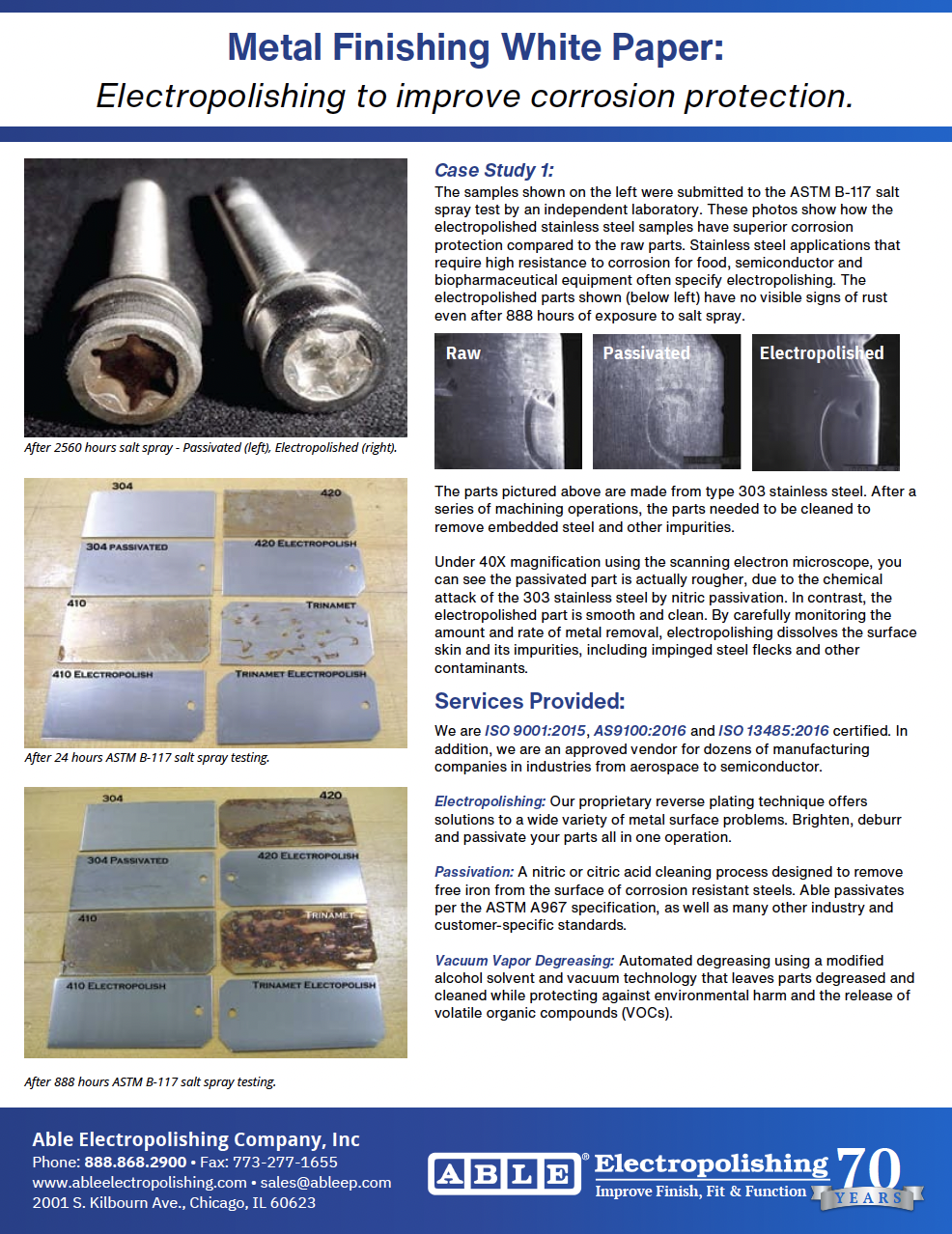

One of the most common applications for electropolishing is to enhance the corrosion resistance of a wide variety of metal alloys, including all grades of stainless steel.

Its superior ability to improve corrosion resistance, while also removing defects left behind by machining processes and improving surface finish by up to 50%, is often a key factor in the decision to specify electropolishing instead of passivation for parts that must withstand exposure to moisture and other corrosive conditions.

Electropolishing leaves metal parts with 30 times the corrosion resistance of passivation alone, while also leaving them in a passivated state.

Download this whitepaper to learn more, including the results of independent salt spray testing comparing the corrosion resistance of passivated and electropolished parts.