- Free Sample

- Request Quote

(773) 277-1600 |

(773) 277-1600 | - ITAR Registered

-

-

-

See for Yourself:

Try Electropolishing for Free

Send us your parts and we’ll electropolish them for free – we’ll even pay for the shipping! Samples are processed in 2-3 days.

Electropolishing removes a microscopically precise layer of surface material, and can be controlled to +/- .0002", depending on the alloy. This degree of precision and consistency, along with the ability to remove a variety of surface imperfections in one process, is why electropolishing is often specified for critical parts such as medical implants and surgical instruments, aerospace components and a variety of other industries.

Electropolishing is a one-stop process for a micro-smooth, ultraclean, corrosion and pathogen-resistant surface finish – with 30 times more corrosion resistance than passivation.

Electropolishing can eliminate the need for additional metal finishing processes like passivation, hand deburring, tumbling, pickling, and cleaning.

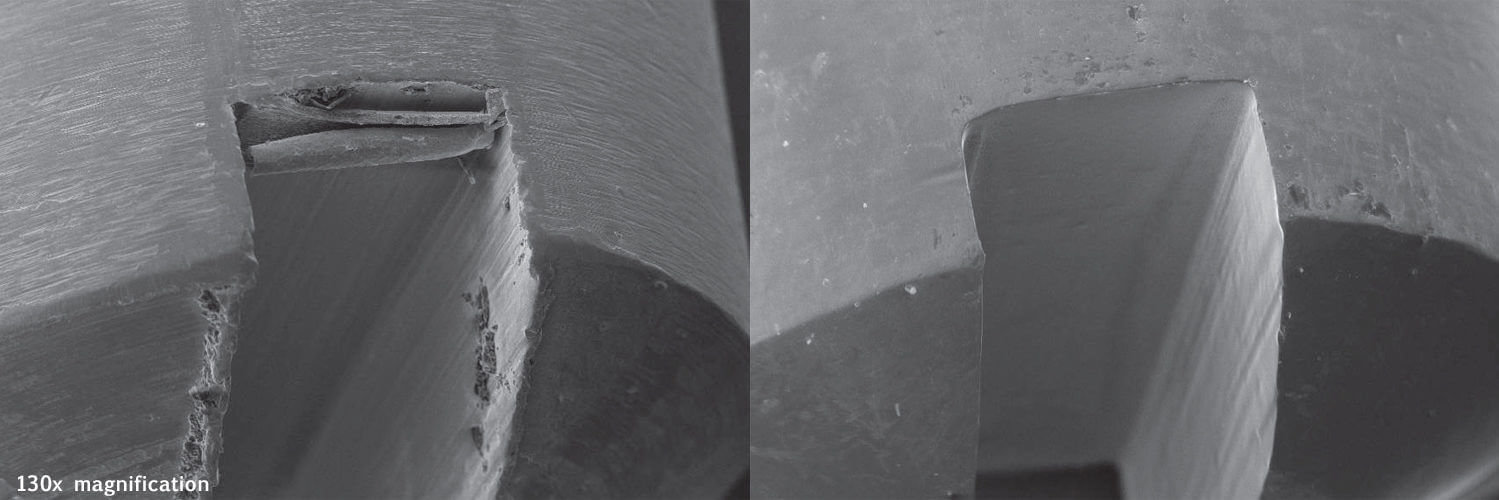

Electropolishing Before & After

Send Us Your Free Sample Parts

- Complete the form on this page

- Fill out and print your packing slip that will arrive by email

- Print the pre-paid shipping label and send us your parts

Companies typically send us 1-10 parts for sample processing. Our address (printed on the shipping label):

Able Electropolishing Co., Inc.

Attn: Sales Engineering

2001 S Kilbourn Ave.

Chicago, IL 60623

Electropolishing vs. Passivation

About Able Electropolishing

For your critical metal parts, you can eliminate burrs, micro cracks and other imperfections left behind in the manufacturing process with precision microfinishing services from Able Electropolishing. You will achieve a high-quality finish with precise, consistent and repeatable results you can count on thanks to a multimillion-dollar investment in robotic automation and deep experience dating back to 1954.

Whether you need electropolishing, passivation, vapor degreasing, or other finishing processes for stainless steel, aluminum, Nitinol, titanium or other alloy, Able is the metal finishing provider of choice for manufacturers of products with no margin for error. More >